Streamline your multipiece inspections

Join this FREE 1-day PolyWorks® seminar to elevate your 3D measurement approach and optimize the way you tackle multipiece inspection projects. Discover the benefits of enhanced reporting for effective communication with colleagues and quick data-driven decisions.

Streamline your multipiece inspections

Join this FREE 1-day PolyWorks® seminar to elevate your 3D measurement approach and optimize the way you tackle multipiece inspection projects. Discover the benefits of enhanced reporting for effective communication with colleagues and quick data-driven decisions.

In this keynote presentation, Marc Soucy, PhD, President and co-founder of InnovMetric, explains how you can eliminate significant time losses and process inconsistencies with digital thread technologies. These technologies establish a single source of truth for dimensional inspection data and automate your data flows to deliver 3D measurement data digitally enterprisewide.

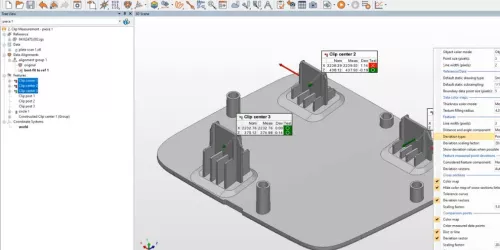

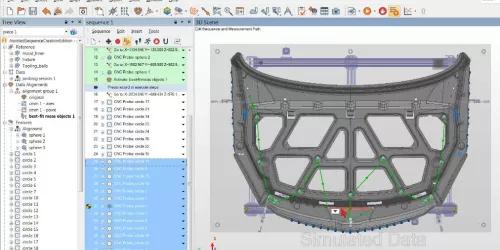

Discover how to optimize the efficiency and flexibility of your part measurement process with PolyWorks|InspectorTM 2025. This 20-minute video showcases new functionalities like auto-alignment for faster scanning, automatic large-part inspection, enhanced GD&T calculations, and assisted CMM sequencing for complex CAD surfaces.

The world has gone digital in a revolutionary way. The digitalization of manufacturing processes should be a natural next step. See how we made the transformation and understand how the PolyWorks enterprise solution can directly contribute to enhancing your company’s competitivity and increasing the value of your expertise.

Managing 3D measurement data is a major challenge. The growing popularity of 3D scanning technologies yields large inspection projects. Discover how you can achieve substantial daily productivity gains by using PolyWorks|DataLoop™.

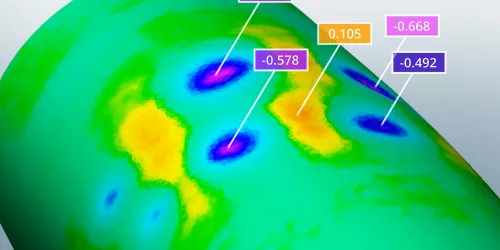

With this new technology, scan your parts and quickly display surface imperfections. Detect bumps, dents, and scratches, monitor part degradation over time, and locate missing functional elements, such as spot welds or rivets.

Learn the benefits of integrating PolyWorks into your production environments.

Discover three preproduction tasks that greatly benefit from our latest innovations.

Let's explore how PolyWorks can enrich your contribution to your enterprise.

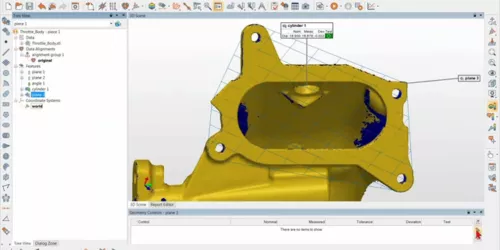

When a part is inspected with the help of its CAD model, the CAD model is used throughout the project to align the part, extract features, and produce pass/fail results. When inspecting a part by scanning without using a CAD model, you go through those same steps obtaining measured-to-nominal deviations but using a different toolset.

With the introduction of PolyWorks|ReportLoop™, a free Excel-based smart reporting solution, you can link spreadsheet cells directly to PolyWorks® inspection project data.

Inspecting a part in PolyWorks|Inspector™ with the support of a CAD model is not always an option. While using CAD models is a very efficient way of getting the nominal geometry required for performing an alignment, obtaining measurement deviations, and driving measurement guidance, when they are not available you can perform part inspection just as well.

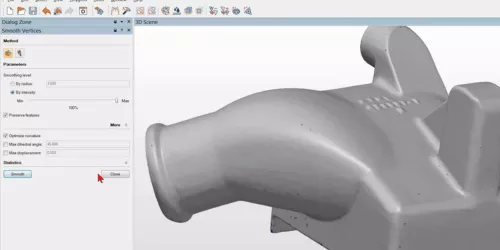

With PolyWorks|Modeler™ Light, quickly clean up surfaces, optimize the size of a model while preserving its topology and dimensional accuracy, and rapidly calculate volume and surface area.

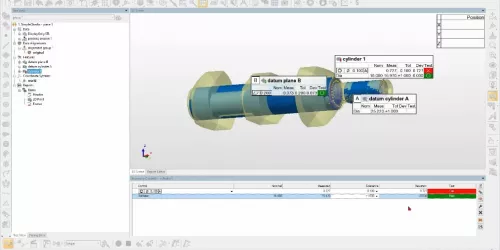

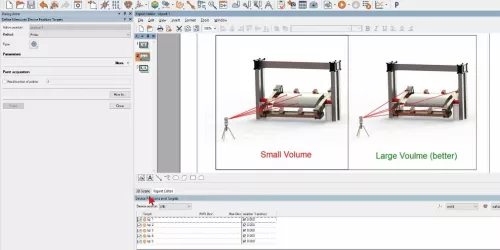

Whether you need to get a complete coverage of your part while scanning, or simply reach measurements that are beyond the range of your device, combining data from multiple part/device setups is a common task for metrologists. PolyWorks|Inspector™ offers a complete set of tools to efficiently and accurately combine data acquired from multiple device positions.

When facing complex metrology challenges, metrology specialists often develop in-house, proprietary measurement techniques that require documentation and support within their company. These measurement techniques can now be implemented directly within PolyWorks|Inspector™.

Creating CNC CMM sequences for projects containing a large number of measurement objects is typically a long process, involving repetitive tasks such as defining tool orientations, avoiding collisions, and finding the optimal object measurement order. PolyWorks|Inspector™ now offers an interactive sequence creation mode that assists users throughout the process.